UHMWPE (Ultra-High-Molecular-Weight Polyethylene) and HDPE (High-Density Polyethylene) are both types of polyethylene, but they differ significantly in their molecular structure, properties, and applications.

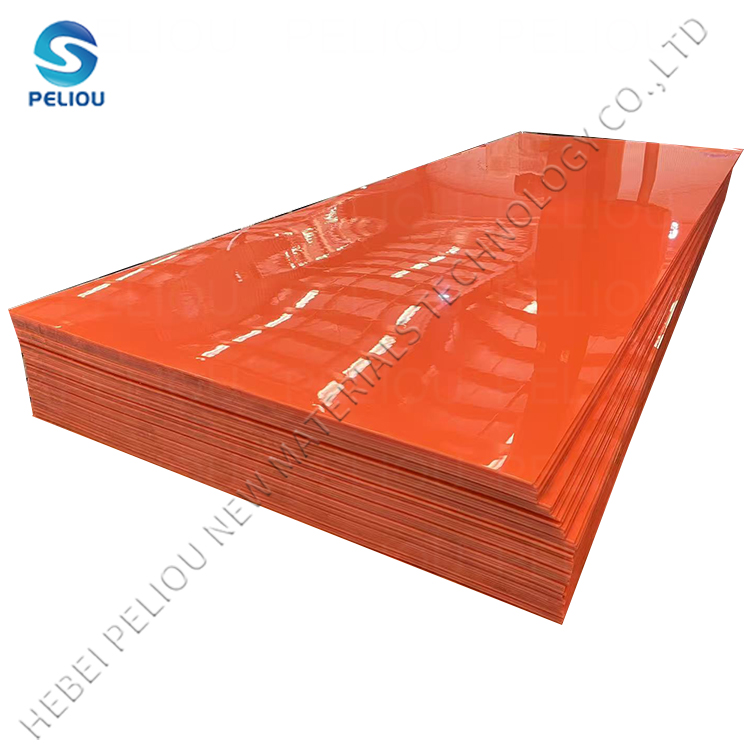

This is orange HDPE sheet:

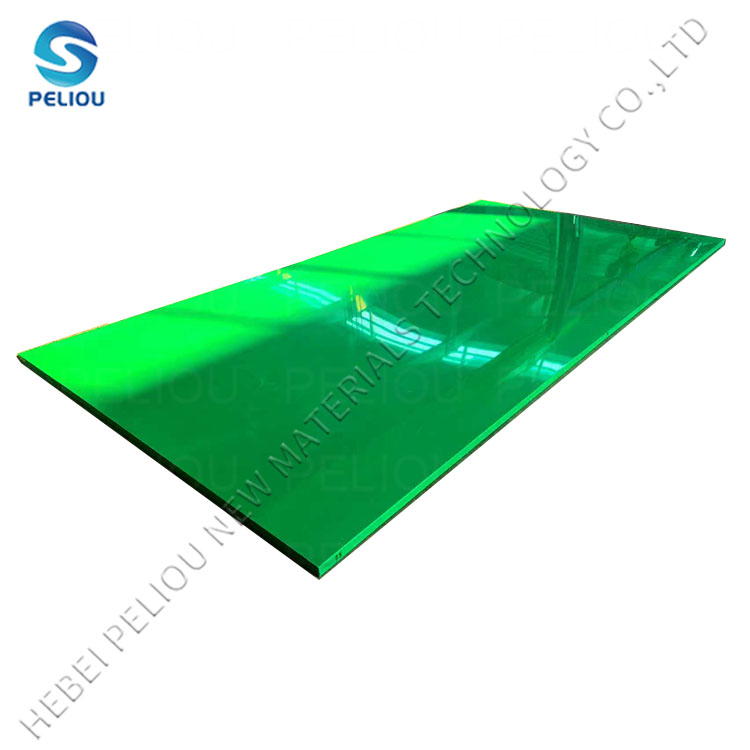

This is green UHMWPE sheet

| Property / Feature | UHMWPE | HDPE |

|---|---|---|

| Full Name | Ultra-High-Molecular-Weight Polyethylene | High-Density Polyethylene |

| Molecular Weight | Very high (3–10 million g/mol) | / |

| Density | ~0.93 g/cm³ | ~0.96 g/cm³ |

| Crystallinity | High | High |

| Tensile Strength | High | Moderate |

| Impact Resistance | Extremely high (excellent toughness) | Good |

| Abrasion Resistance | Excellent (very low wear) | Good |

| Friction Coefficient | Very low (slippery) | Moderate |

| Machinability | Good (often machined into parts) | Often used in molded form |

| Processability | Difficult to melt and mold (no clear melt point) | Easy to process via molding or extrusion |

| Typical Applications | Bulletproof vests, medical implants, liners, conveyor guides | cutting board,hockey shooting pad,furniture |

| Cost | Higher | Lower |

UHMWPE is a specialized, high-performance plastic known for exceptional impact, wear, and chemical resistance, commonly used in demanding applications like armor, biomedical implants, and industrial components.

HDPE is a more general-purpose plastic, widely used due to its ease of processing and good strength and durability, found in products like containers, pipes, and plastic bags.

Let me know if you need help choosing one for a specific application.