The most durable outrigger pads are usually made of ultra-high molecular weight polyethylene (UHMWPE), which performs well in extreme environments due to its excellent wear resistance, impact resistance, and chemical stability.

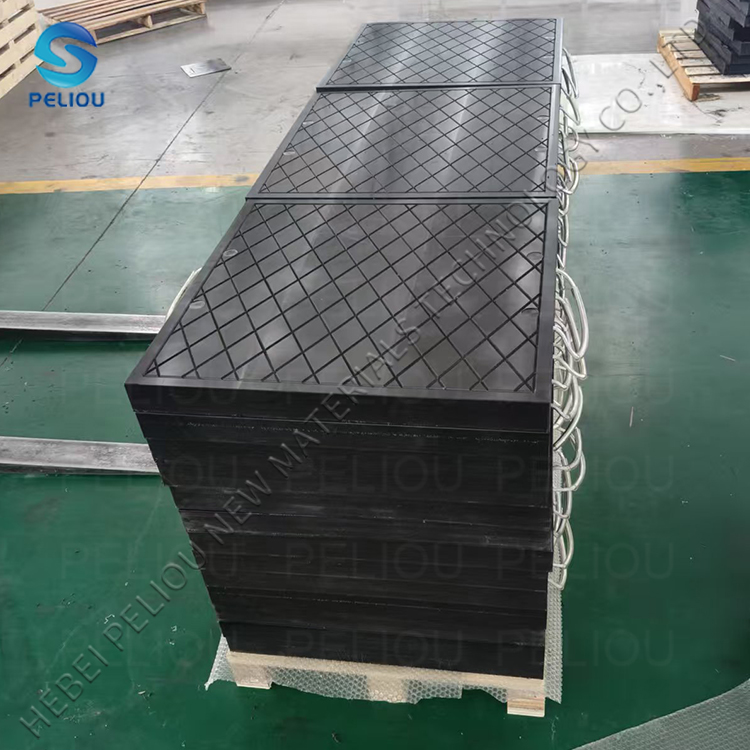

1. Ultra high molecular weight polyethylene (UHMWPE) outrigger pad

-Advantages:

-Wear resistance: More than 10 times higher than ordinary polyethylene, suitable for high friction scenarios such as conveyor belts and guide rails.

-Impact resistance: able to withstand repeated impacts and not easily crack (such as dock pads and mechanical protection).

-Self lubrication: Low friction coefficient, no need for additional lubrication (suitable for food or pharmaceutical equipment).

-Chemical resistance: resistant to acid, alkali, and solvent corrosion (commonly used in chemical equipment).

-Low water absorption: Dimensional stability in humid environments.

2. Suggestions for selection

-Heavy industry/high wear environment: UHMWPE is preferred (such as mining machinery, steel plants).

-Chemical exposure scenario: Polyethylene grade resistant to specific chemicals

UHMWPE pads are the best choice for durability, especially suitable for harsh working conditions; If conditions permit, priority should be given to products certified by ISO or ASTM standards to ensure performance.

3. Other durability factors

-Thickness and Design: Increasing thickness or adding anti slip patterns can extend lifespan.

-Color: Black UHMWPE usually contains anti UV agents and is suitable for long-term outdoor use.